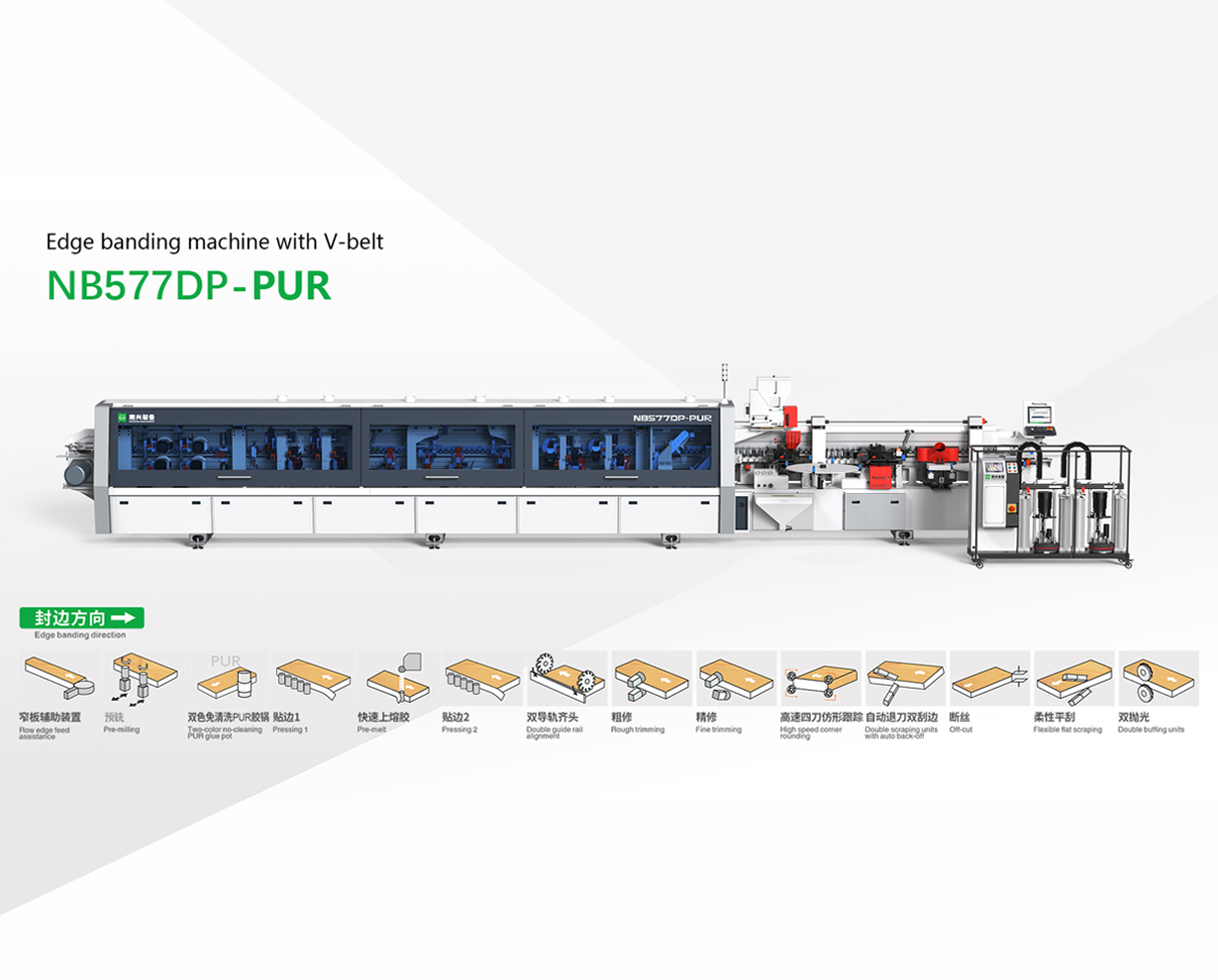

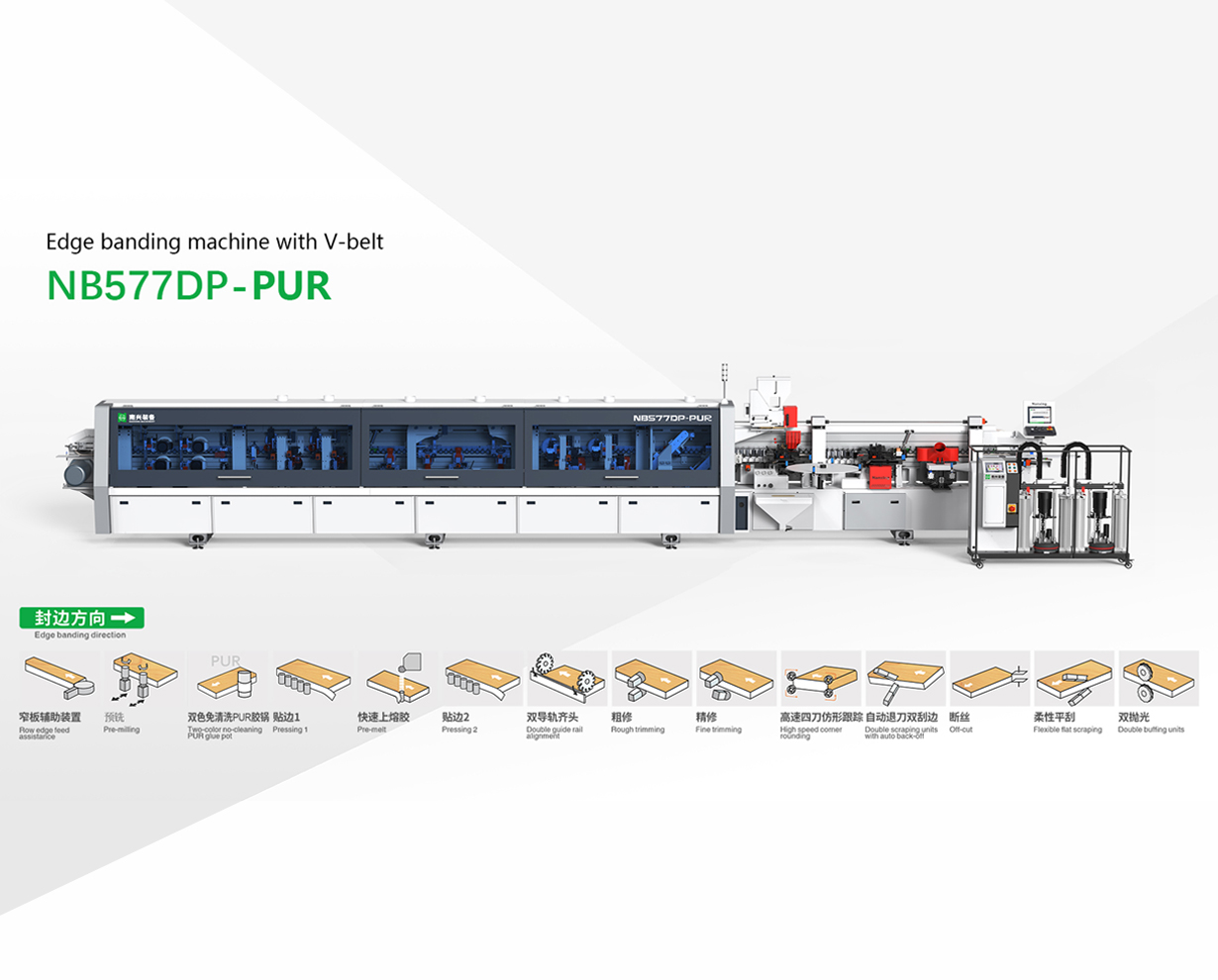

Nanxing Edge Banding Machine NB577DP-PUR with V-Belt&Double Gluing Units

FESTURES

- Top presser Fiber reinforced v-belt

- Feeding assistance for narrow edge

- Spraying device (Release agent)

- Pre-milling double milling cutter

- 2 Sets of pre-heating

- Coil tape bracket*2

- Tape snipping*2

- Gluing 1: PUR gluing system with 2 color tank

- Pressure rollers

- Gluing 2: Pre-melter gluing system

- Auto glue pumping + 25kg glue basic

- Pressure rollers

- Auto lubrication system

- Dual rails for end cutting

- Rough trimming

- Fine trimming

- Corner rounding with 4 motors

- 23. 2 sets of scraping units with pneumatic moving back function

- Off cut device

- Pneumatic flat scraping

- 26. Clean agent sprayer

- Two sets of oscillating Buffing

- Remote switch and indicator light

- 10’’ touch screen

- Production report

Safety device

Feed Baffle:

- Used to limit the spacing between boards and protect the normal operation of various workpieces.

- It provides over-thickness protection for workpieces; if the board exceeds the current thickness, the conveyor belt will stop

- Interval feeding detection system

- E-Stop

TECHNICAL SPECIFICATIONS

- Panel length: ≥120 mm ≥200mm with corner rounding

- Panel width: Long edge ≥40 mm; Short edge ≥60 mm

- Panel thickness: 9-60 mm

- Min. panel size 120×60mm (4 side edge banding) 200×40mm (long side edge banding)

- Edge tape thickness: 0.4-3 mm

- Feeding speed: 18/22/26 m/min; (22m/min with corner rounding)

- Power supply: 380 V; 50 Hz

- Air pressure required: 0.7MPa

- Total power: 34 Kw

- Approx. weight: 4,620 kg

- Overall dimension: 11,750*1,450*1,850 mm